Our Expertise

Our comprehensive in-house capabilities encompass every stage of production: processing raw steel, heat treatment, stamping, grinding, CNC machining, finishing/polishing, and meticulous quality assurance. This complete control ensures high-quality products and on-time delivery, every time.

Expert Heat Treatment

The performance of a stainless steel frame depends heavily on proper heat treatment. That's why we invest in the best. Our team of metallurgical experts, with over 20 years of experience, utilizes state-of-the-art furnaces from Germany and Japan to deliver optimal, consistent heat treatment. This meticulous process ensures the highest quality, durability, and performance for every frame.

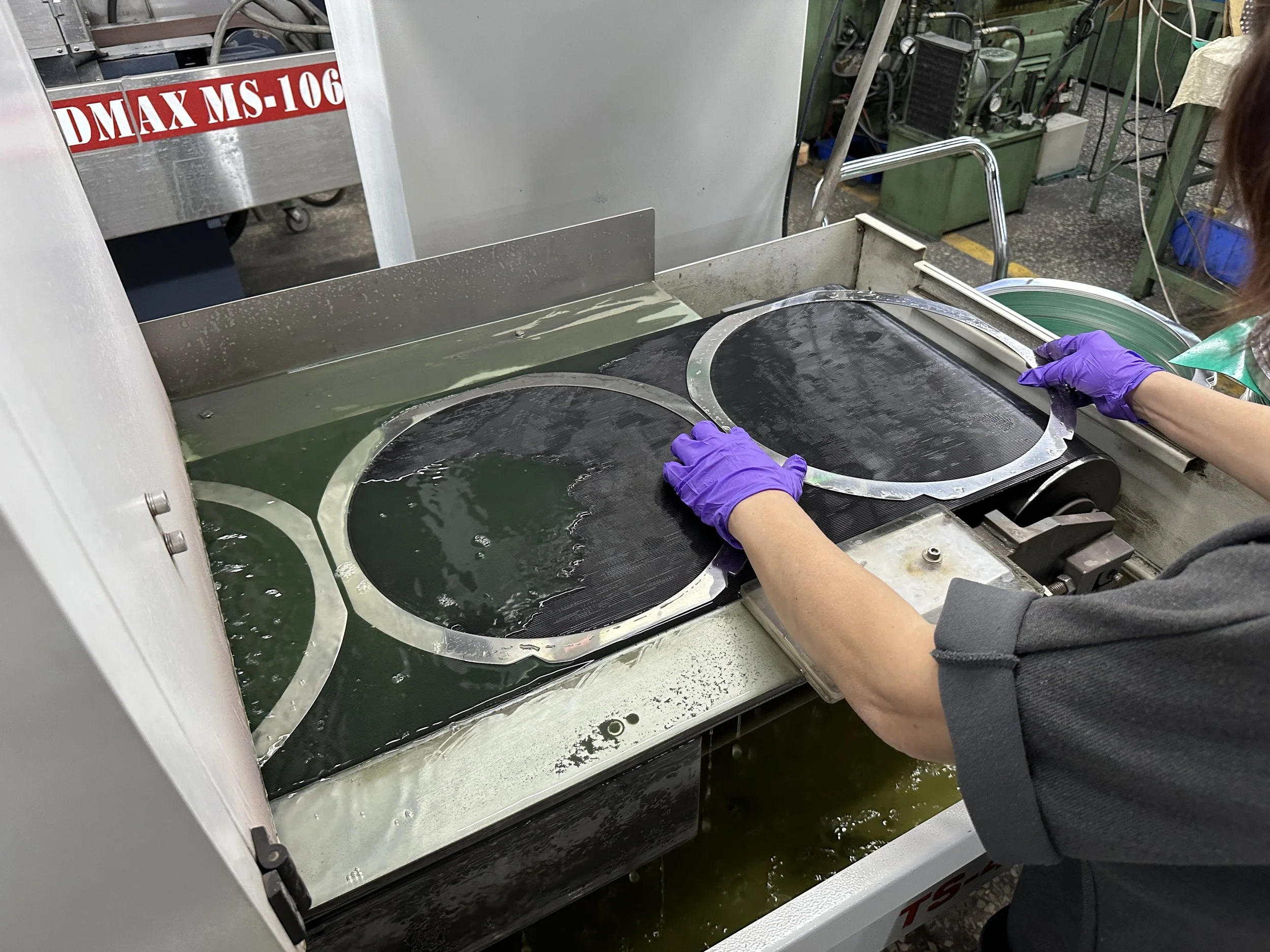

Quality is paramount. That's why we handle every aspect of manufacturing in-house. From the initial heat treatment to cutting, washing, polishing, and final packaging, our state-of-the-art facilities ensure the highest quality standards are consistently met. This complete control allows us to maintain meticulous oversight and deliver superior products.

In-House Manufacturing

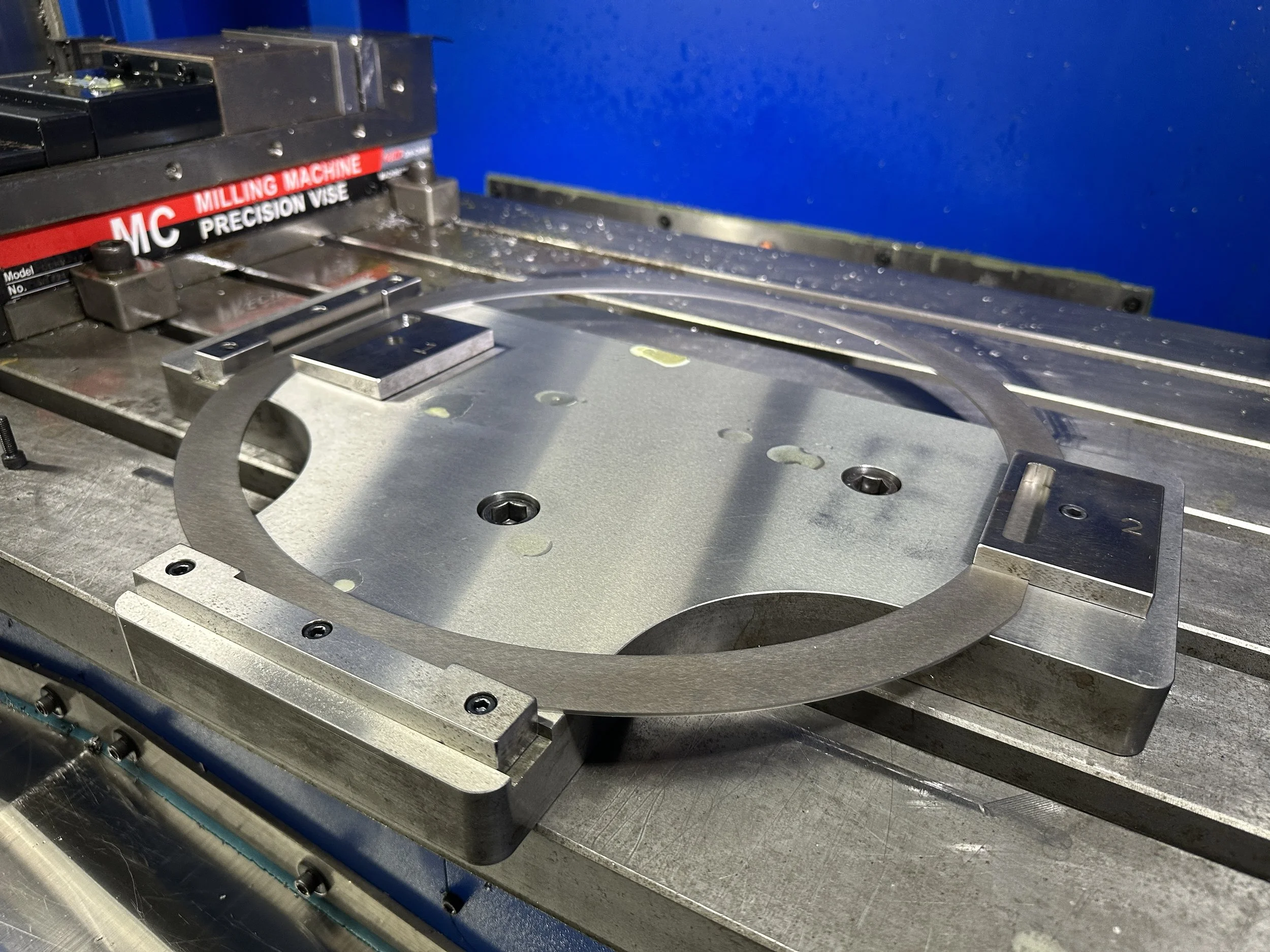

Our facility houses over 100 machines, encompassing metal stamping, laser cutting, CNC, grinding, milling, sanding, and washing, enabling us to execute any custom modification. From laser etching logo or QR codes to milled barcode pockets, most modifications are completed at minimal or no added cost. We specialize in meeting exacting specifications for flatness, thickness, and other critical dimensions.

Custom Requests

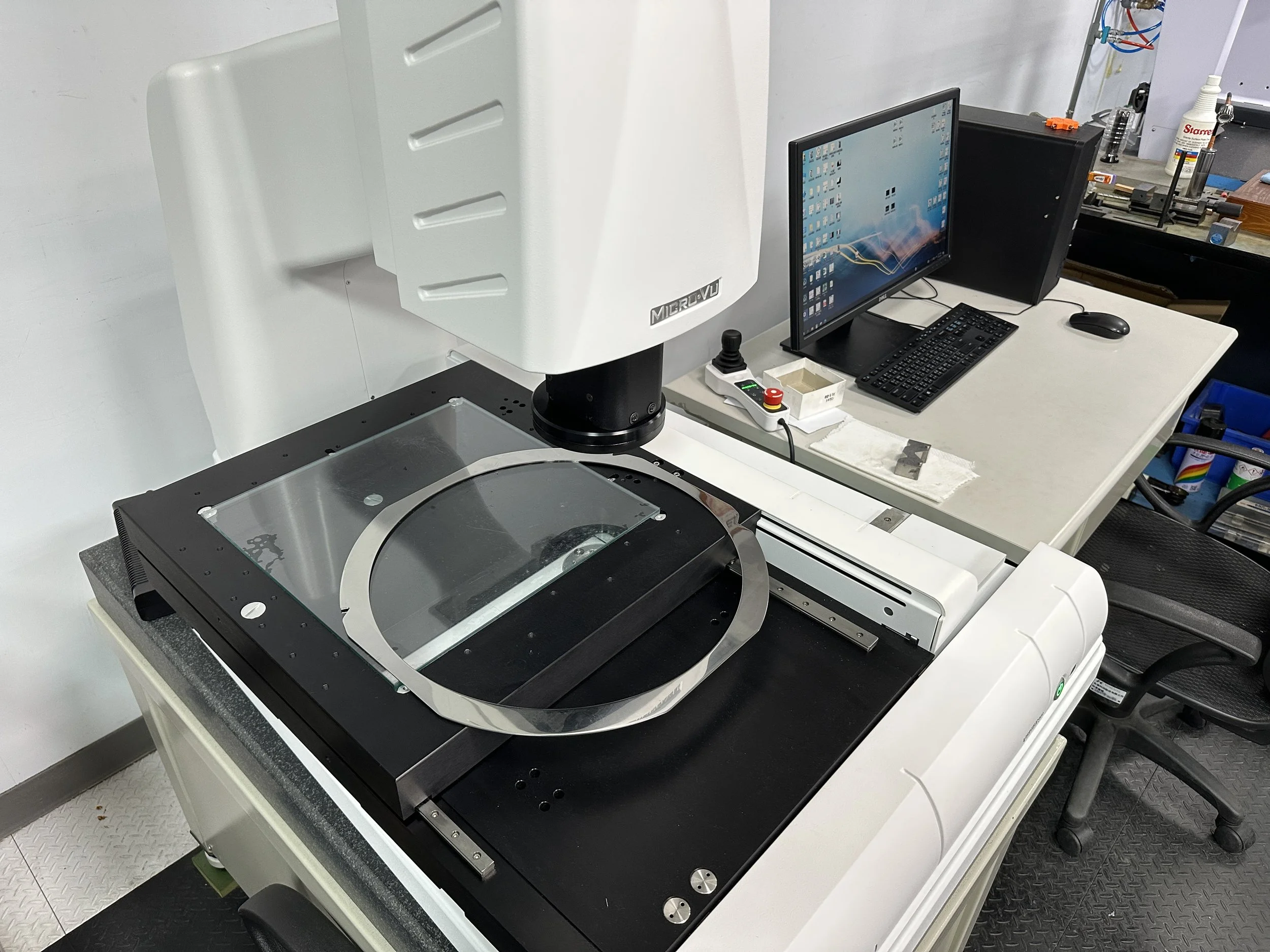

We leave nothing to chance. Our professional QA labs are outfitted with cutting-edge technology, including measuring machines, 3D scanners, and metallurgical microscopes. This comprehensive suite of equipment allows our expert technicians to meticulously inspect each wafer frame, guaranteeing strict adherence to customer specifications and the highest quality standards. We inspect 100% of the frames that leave our facility.